Portfolio

Welcome to my portfolio—a window into my passion for automotive engineering and the projects that fuel it. As a second-year Material Science Engineering student at the University of Toronto and a dedicated member of the Formula SAE (FSAE) University of Toronto Formula Racing Team, I’ve immersed myself in the world of automotive design and innovation. Here, you’ll find a collection of my work that marries theoretical knowledge with hands-on experience, showcasing my journey from rebuilding a classic Pontiac Firebird Trans Am to engineering cutting-edge components for electric racing cars.

Engineering Innovation in Action

Dive into the detailed drawings and designs where every line and measurement reflects precision and purpose. I’ve crafted cost-effective suspension parts using SOLIDWORKS, achieving a 5% weight reduction without compromising strength. The drivetrain sprocket you see is more than a component; it’s a result of simulating real-world forces in ANSYS to optimize performance for our 2024 electric Formula racing car. Moving forward, my work on the wheel center design for the 2025 season embodies extensive research and material testing, aiming to push the boundaries of what’s possible on the track.

Each project is a testament to my commitment to excellence and innovation in automotive engineering. Through meticulous analysis and creative problem-solving, I strive to develop solutions that enhance performance, safety, and efficiency. I invite you to explore these projects and join me on this exciting journey as I continue to turn complex engineering challenges into tangible, high-performance realities.

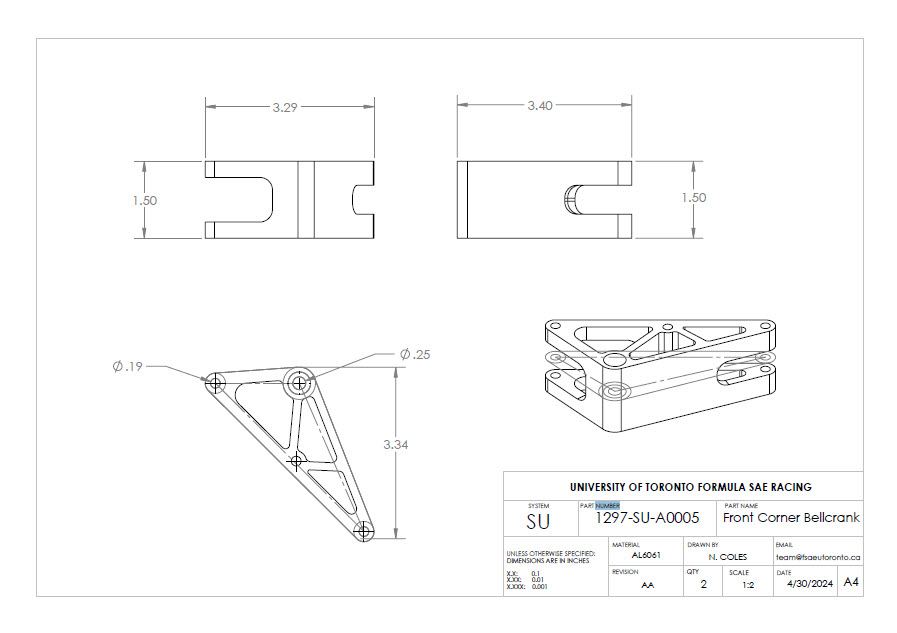

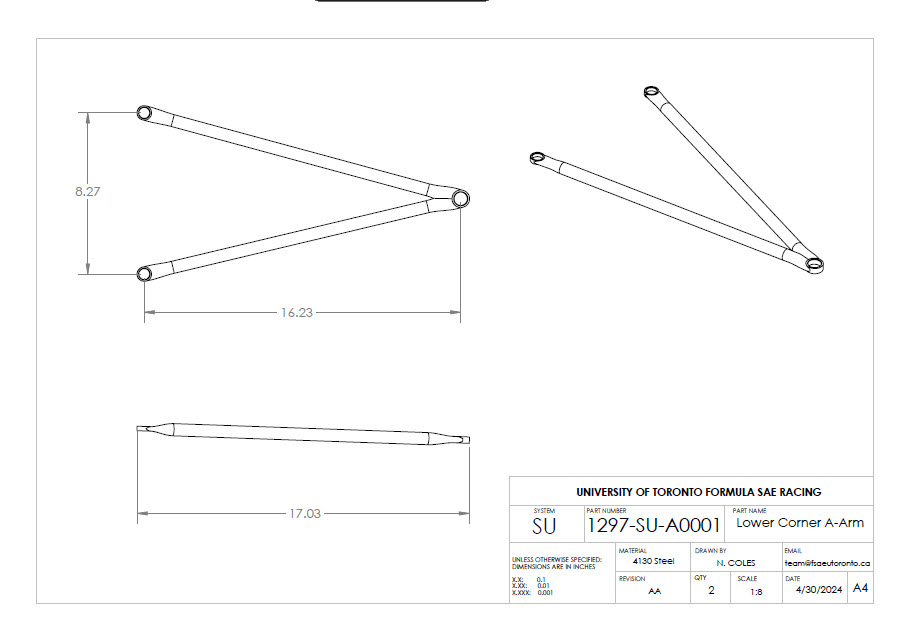

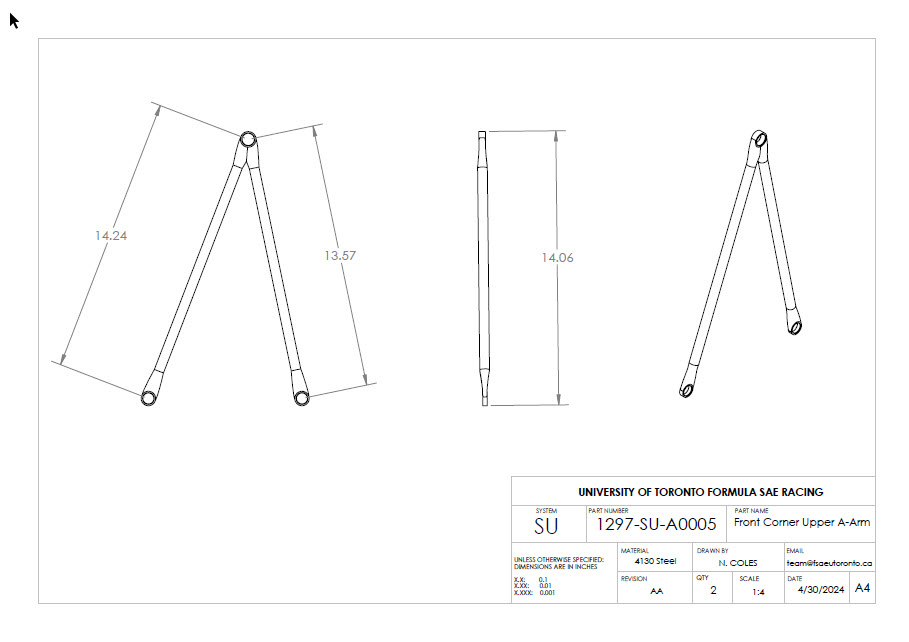

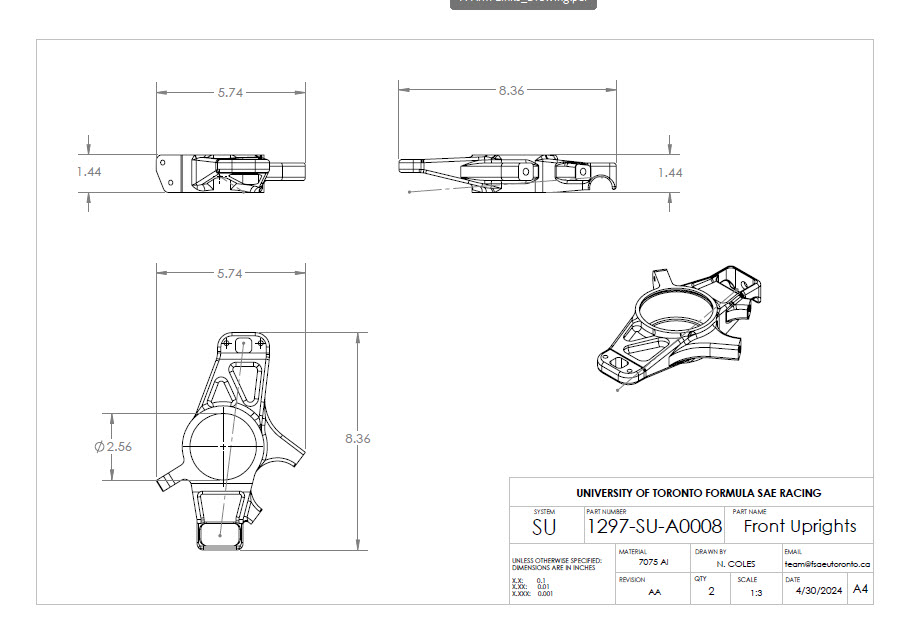

The 4 Cost Drawings

I am creating drawings for the UTFR Suspension Team, and it’s the corresponding SOLIDWORKS parts. By dimensioning them and creating the drawings, I calculated the manufacturing cost of each part from the drawings from knowing the material, weight and dimensions.

SU-Front Corner Bellcrank

SU-Front Corner Lower A Arm

SU-Front Corner Upper A Arm

SU-Front Corner Upright

Drivetrain Sprocket

I created a Main Drive Sprocket for the Drivetrain Section for the 2024 Formula Racing Car.

The sprocket connected from the powerful electric motor on the car to the differential where the power was put on the wheels.

Using ANSYS I simulated real load cases of forces we measured the car experienced on the track and applied it into the software to see the weak points in the structure and getting as much weight reduction as possible.

Suspension Wheel Centre Sprocket

For the Suspension Section I worked on the new Wheel Centre Design for our 2025 Formula Racing Car for the upcoming season of FSAE Competitions happening in North America and Europe in the Spring and Summer of 2025.

Doing extensive research on notes, data and case studies from past years of the team helped me create the new Wheel Centre Design.

Testing different types of materials and comparing to our manufacturing capabilities, I picked the best material possible for the wheel centres. I am in the process of doing ANSYS simulation work putting in load cases needed to simulate real driving conditions. Things such as longitudinal forces, lateral forces, called bump, brake.

Using this information, I analyze the structure to identify weak points and areas where we can safely reduce weight. The goal is to strike a balance between minimizing material use and maintaining structural integrity, ensuring the car is both lightweight and durable for optimal performance on the track.